2025-11-29T06:46:03

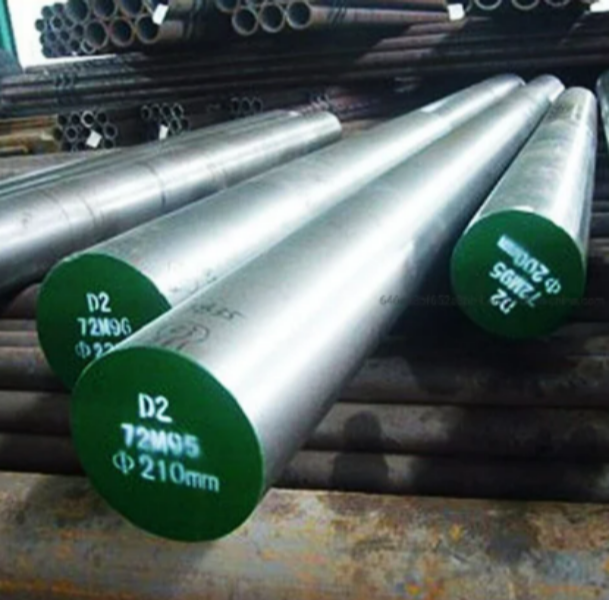

HCHCR D2 Steel – High Carbon High Chromium Tool Steel for Superior Wear Resistance HCHCR D2 Steel is a premium-grade high carbon, high chromium tool steel widely recognized for its exceptional wear resistance, hardness, and dimensional stability. Due to its air-hardening properties and high alloy content, D2 steel is the preferred choice in industries that require long-lasting tool performance under severe operating conditions. With a hardness range that can exceed 60 HRC after proper heat treatment, HCHCR D2 delivers outstanding cutting efficiency and edge retention. One of the biggest advantages of HCHCR D2 Steel is its excellent resistance to abrasion and wear. This makes it ideal for manufacturing tools that are exposed to continuous friction, impact, and heavy loads. Common applications include blanking dies, forming dies, shear blades, punches, industrial knives, trimming tools, and cold work tooling. Its ability to maintain sharpness and structural strength for extended periods significantly reduces tool replacement frequency and boosts productivity. HCHCR D2 Steel also offers excellent dimensional stability during heat treatment, which ensures accurate and consistent results for precision components. Its high chromium content provides improved corrosion resistance compared to conventional carbon steels, making it suitable for environments where moisture and mild chemical exposure are present. The steel’s machinability is moderate, but with the right tooling and machining parameters, it achieves precise and clean finishes. Additionally, D2’s uniform hardness and deep hardening properties allow it to be used effectively in large and complex tool geometries without compromising performance. Industries such as automotive, fabrication, stamping, plastic molding, and metal cutting rely heavily on HCHCR D2 Steel for producing high-strength and long-life tooling components. With its unmatched strength, durability, and wear resistance, HCHCR D2 Steel stands out as a highly dependable material for cold work applications.

Have a question? Ask here!

Required fields are marked *