2024-08-15T06:55:07

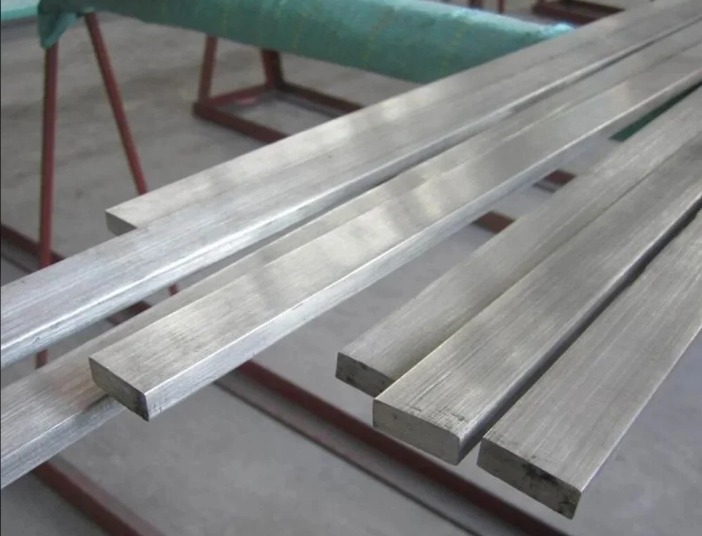

M 2 High Speed Steel Flats Supplier In Delhi M2 High-Speed Steel (HSS) flats are flat bars or sheets made from M2 steel, a popular high-speed steel known for its superior hardness, wear resistance, and ability to retain sharpness even under high temperatures. These flats are widely used in the manufacturing of cutting tools and other high-performance industrial components due to their exceptional properties. Composition and Properties of M2 High-Speed Steel Flats M2 steel is an alloy that typically contains carbon, tungsten, molybdenum, chromium, vanadium, and cobalt. The precise combination of these elements gives M2 steel its distinctive properties: Hardness: M2 HSS flats exhibit excellent hardness, often in the range of 62-65 HRC (Rockwell Hardness Scale). This hardness is crucial for cutting tools that must retain a sharp edge over prolonged use. Wear Resistance: The high hardness of M2 steel translates to superior wear resistance, making these flats ideal for applications where the material is subject to significant friction and abrasion. Heat Resistance: One of the key features of M2 steel is its ability to retain its hardness at high temperatures, up to 600°C (1112°F). This "red hardness" property is essential for high-speed machining and cutting operations where the tool is exposed to significant heat. Toughness: Despite its high hardness, M2 steel maintains good toughness, reducing the risk of chipping or breaking during use. Applications of M2 High-Speed Steel Flats M2 HSS flats are used in a variety of applications across different industries: Cutting Tools: M2 flats are commonly machined into cutting tools such as end mills, drills, taps, and reamers. These tools are used in machining processes to cut through tough materials like stainless steel, titanium, and high-strength alloys. Blades and Knives: The flats are also used to produce industrial knives and blades for applications requiring precision and durability, such as in the paper, textile, and food processing industries. Forming Tools: M2 steel flats are used to manufacture forming tools like punches and dies, which are essential in metalworking operations like stamping and forging. The toughness and wear resistance of M2 steel make it ideal for tools that need to withstand repeated impact and pressure. Molds and Dies: In addition to cutting and forming tools, M2 flats are used in the production of molds and dies for plastic injection molding and metal casting, where durability and precision are critical. Advantages of Using M2 High-Speed Steel Flats The primary advantages of M2 HSS flats include: Long Tool Life: The combination of hardness, wear resistance, and heat resistance ensures that tools made from M2 flats have a long service life, reducing the need for frequent replacements. High Performance: M2 steel's ability to maintain its properties at high speeds and temperatures allows for faster machining and cutting, improving overall productivity. Versatility: M2 HSS flats can be used in various applications, making them a versatile material for toolmakers and manufacturers. Conclusion M2 High-Speed Steel flats are an essential material in the tool-making industry, offering a perfect balance of hardness, toughness, and heat resistance. Their versatility and durability make them an ideal choice for manufacturing a wide range of cutting, forming, and machining tools, ensuring high performance and longevity in demanding industrial applications.

Have a question? Ask here!

Required fields are marked *