2026-01-13T05:49:16

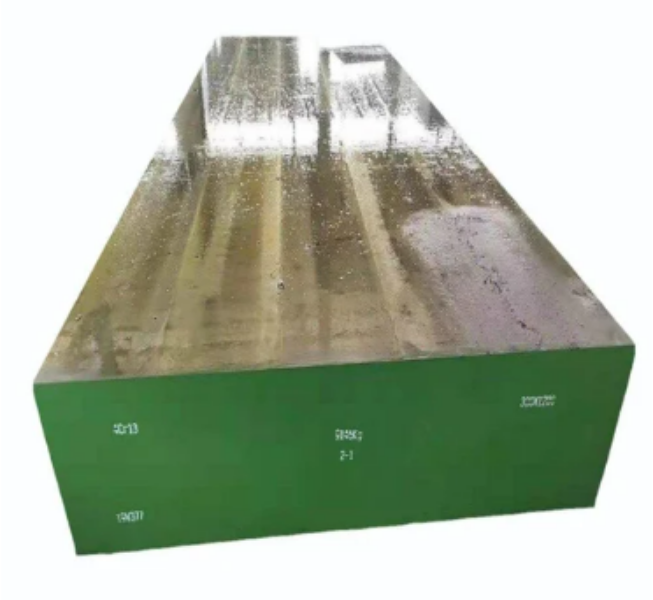

A Rectangular Die Steel Block is a precision-engineered steel product widely used in tooling, die making, and heavy engineering industries. Manufactured from high-quality die steel grades such as D2, D3, H13, P20, or EN series steels, these blocks are designed to deliver excellent strength, wear resistance, and dimensional stability under demanding working conditions. Rectangular die steel blocks are primarily used for the fabrication of dies, molds, punches, press tools, and other critical tooling components. Their rectangular shape provides uniform cross-section and stability, making them ideal for machining complex profiles and maintaining tight tolerances. These blocks are especially suited for cold work and hot work applications depending on the selected steel grade. One of the major advantages of rectangular die steel blocks is their ability to withstand high compressive loads and repeated stress without cracking or deformation. Proper heat treatment enhances hardness, toughness, and resistance to abrasion, ensuring long tool life and consistent performance. Grades like D2 and D3 offer superior wear resistance, while H13 and P20 are preferred for applications involving high temperatures and thermal cycling. These die steel blocks are typically supplied in annealed or pre-hardened condition, allowing easy machining, drilling, and shaping before final heat treatment. After hardening and tempering, the blocks achieve optimal mechanical properties required for precision tooling. Their fine-grain structure ensures better surface finish and reduces the risk of distortion during processing.

Have a question? Ask here!

Required fields are marked *